Services

Procurement is one of the most important phases within the system, it could the difference between hitting a deadline or missing it completely.

- Complete kits of parts procured from State of the Art equipped suppliers fully labelled for full traceability along with Assembly part number, component quantity and component location

- Obtain accurate and up to date information on lead times for all materials.

- Secure stock with distributors for long lead time items.

- Locate obsolete or scarce stock on the international markets.

- Where possible consolidate requirements across all your projects to obtain volume pricing.

- Propose low cost alternatives for high volume items.

- Constantly review the earliest supply of your components so that your projects can be release to manufacture on time.

Surface Mount Assembly has become our mainstay of business at B W Electronics utilizing our modern Surface Mount Process. A great deal of products quoted on these days are surface mount, but still very often found are a the combination with conventional through hole components too.

- Prototype, Low or Medium Volume Assembly.

- Full anti-static precautions

- AOI ability for Pre and post Reflow

- Surface mount placement by manual or automatic pick and place.

- Components size: from 0402 to 35 mm sq. (Up to 10mm sq. using on-board camera); max height 10.5mm; minimum lead pitch 0.5mm

- Components range: Chip, Melf, Mini-melf, cylindrical components, transistors, SOT diodes, integrated circuits, PLCC and LCCC integrated circuits, trimmers, inductors, connectors, aluminium electrolytic capacitors. BGA, LGA and QFN placement.

- Hot air reflow

The products manufactured at BW Electronics are as diverse as simple single sided PCBs with only a few components, to complex mixed technology

- Our staff are highly trained to the IPC 610 Standards providing consistently high-quality through-hole PCB assembly.

- Progressive Line Build

- Cropmatic Line Build

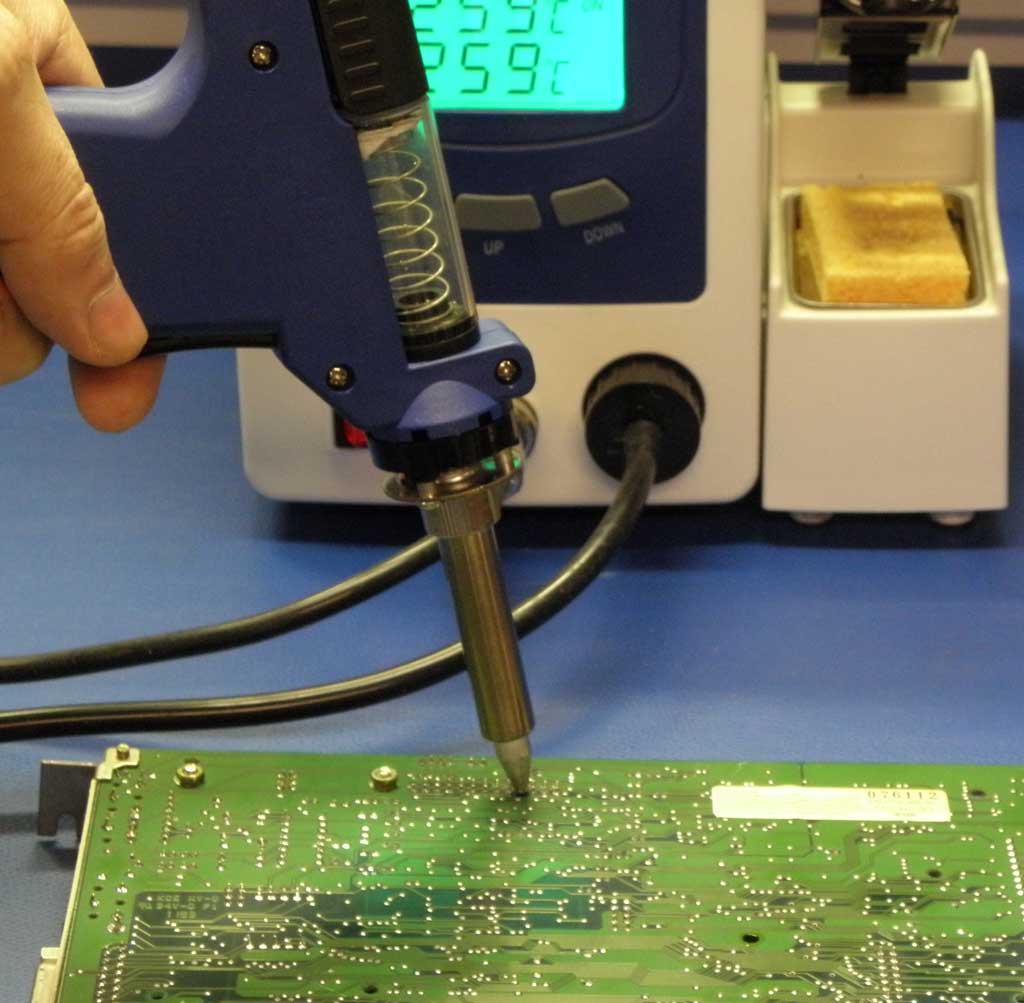

- Lead Free Wave soldering CMS400LF

- Desoldering stations for accurate repair

- RoHS compliant and legacy components

- All soldering equipment is regularly calibrated

- additional services for the final finishing of the product, such as conformal coating and complete PCB encapsulation

As well as PCBs, we manufacture cable assemblies, looms, harnesses and complete chassis assemblies. We can accommodate dedicated customer specific cells for performing final product assembly which includes the assembly and integration of chassis, power supplies, cables, PCBA's along with system configuration and functional test. This facilitates us to manufacture complete 'box build' level to ship to stock or direct to your customer

- various cable types, including coaxial

- Bespoke cable assembly services

- Development of tooling and dedicated production cells

- Wire preparation with automatic cut, strip and termination

- Cable assemblies are continuity tested

- Improving product quality, cost and assembly efficiency

To support the supply commitments of our customers,we offer repair, rework, re manufacture, upgrade and modification services.

- Fault diagnostics-comprehensive analysis of faults found can be fed back to you for future product improvements

- Your product has been discarded by the consumer for one (or more) of the following reasons: fashion/cosmetics/ageing functionality/legislation/choice. Therefore, it requires re-manufacture and/or repackaging

- Economical repair

- Product Modification